HMI / PLC Based Plating Panel

Price 80000.0 INR/ Piece

HMI / PLC Based Plating Panel Specification

- Usage

- Gold Plating

- Condition

- New

- Size

- Standard Sizes

- Product Type

- Customize product

- Application

- Plating Applications

- Color

- All Color

HMI / PLC Based Plating Panel Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 15 Days

About HMI / PLC Based Plating Panel

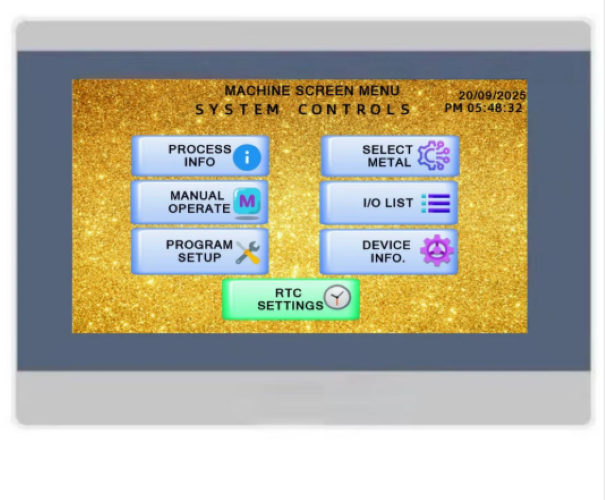

This is acustomized productthat can be developed specifically for yourplating and surface finishing applications.

Based on your process requirements, we can design and build asmart automation solutionusingHMI and PLC, along with acomplete control paneltailored to your needs.

These customized systems can be developed for applications such as:

-

Electroplating Machines

-

Electropolishing Machines

-

Anodizing Plants

-

Zinc / Nickel / Chrome Plating Plants

-

Barrel Plating Machines

-

Rack Plating Machines

-

Automatic Plating Lines

-

Pre-treatment & Rinsing Tanks Automation

-

Rectifier Control Panels

-

Chemical Dosing and Filtration Systems

-

Drying & Heating Ovens

Advanced Automated Plating Solution

Our HMI/PLC Based Plating Panel integrates human-machine interface and programmable logic controls, providing seamless management of plating operations. Built to streamline complex processes, it delivers quality-assured performance for gold plating applications, making it ideal for manufacturers and traders seeking dependable, user-friendly equipment.

Standard Sizes and Customizable Options

Choose from a variety of standard sizes to fit your workspace and specific requirements. With panels available in all colors, you can match existing aesthetics or branding. Each panel is crafted new, ensuring durability and long service life for demanding industrial environments.

Exceptional Performance for Gold Plating

This panel is engineered to facilitate precise gold plating, offering reliable automation and monitoring. By controlling variables such as current, temperature, and cycle time, the panel promotes consistent results and reduces operational errors in both small-scale and large-scale setups.

FAQs of HMI / PLC Based Plating Panel:

Q: How does the HMI/PLC based plating panel enhance gold plating operations?

A: By integrating human-machine interfaces and programmable logic controllers, the panel automates key aspects of gold plating processes, ensuring precise control and improved operational efficiency with minimal manual input.Q: What sizes and colors are available for this plating panel?

A: The panel is available in all standard sizes and comes in a wide range of color options, allowing users to select specifications that best suit their facility and branding.Q: When should I use an HMI/PLC based panel in plating applications?

A: It is recommended for any gold plating setup where accuracy, process consistency, and automation are desired, especially in industrial environments seeking to optimize output and quality.Q: Where is this panel manufactured and supplied from?

A: This panel is manufactured, traded, and supplied by trusted sources in India, ensuring high-quality construction and local support for installation and maintenance.Q: What is the installation process for the HMI/PLC plating panel?

A: Installation is straightforward; the panel is designed to fit standard fixtures. After physical mounting, connections to plating machinery and power sources are made, followed by software configuration tailored to your process needs.Q: How do I operate and maintain the plating panel for longevity?

A: Routine operation involves using the intuitive HMI interface. For maintenance, periodic inspection and cleaning are recommended, along with timely software updates provided by the manufacturer to ensure sustained performance.Q: What benefits does this panel offer to manufacturers and suppliers?

A: Manufacturers and suppliers using this panel experience improved productivity, reduced process errors, and enhanced control over plating quality, resulting in better finished products and higher operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hmi Touch Panel Category

Delta DOP-107BV 7 Inch hmi

Price 9497.0 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Usage : 7 INCH HMI

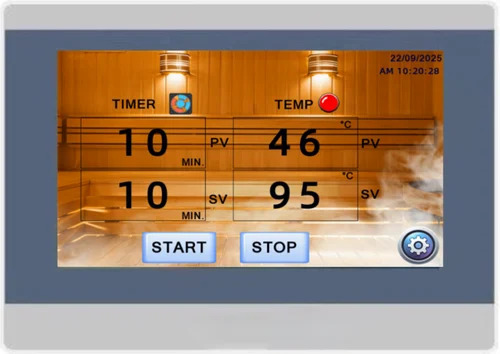

Souna Bath Controller( HMI Based Touch Screen)

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Voltage : 230 Volt (v)

Size : 7" Screen Size

FE7043WE Flexem HMI

Price 5700 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Voltage : 24V DC Volt (v)

Usage : Industrial

Size : 4.3" Screen Size

FLEXEM HMI FE3343C

Price 5200 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Usage : Industrial

Size : 4.3" Screen Size

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry