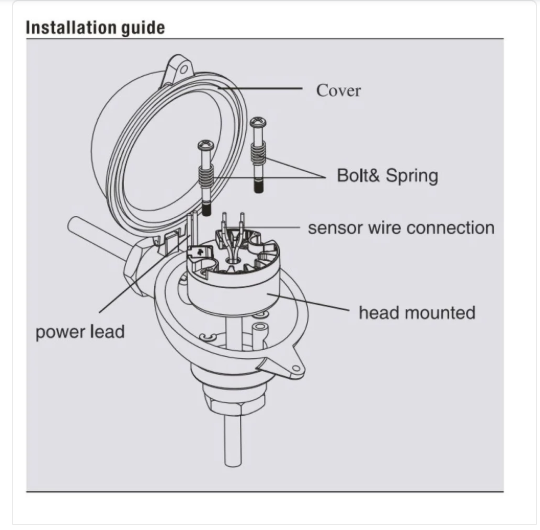

Rtd Head Mounted Temperature Transmitter

Price 800.0 INR/ Piece

MOQ : 1 Piece

Rtd Head Mounted Temperature Transmitter Specification

- Efficiency

- 95%

- Humidity

- 10-90%

- Usage

- Industrial

- Size

- Standard Sizes

- Condition

- New

- Product Type

- TRANSMITTER

- Application

- Transmission

- Power Mode

- Electric

Rtd Head Mounted Temperature Transmitter Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 6 Days

About Rtd Head Mounted Temperature Transmitter

Universal input, support RTD,:Pt-100, Cu50, Cu100Thermocouple: K,J,E,T,S,R,B,N

2 wires 4-20mA output

Input configurable via PC Software and Android smart phone

Built in Cold Junction Compansation

Can be installed in Form B connection box

Industrial Application and Efficiency

This transmitter is engineered for demanding industrial environments, providing consistent performance with 95% efficiency. Its compatibility with a broad humidity range (10%-90%) makes it ideal for use in factories, processing units, and other challenging settings, ensuring reliable operations regardless of ambient conditions.

Seamless Integration and Usage

Designed to fit standard sizes, the RTD head-mounted transmitter simplifies installation and maintenance. It can be easily integrated with existing process systems, supporting electric-powered operations, and caters to a wide array of temperature measurement and transmission requirements in industrial plants.

FAQ's of Rtd Head Mounted Temperature Transmitter:

Q: How does the RTD Head Mounted Temperature Transmitter work in industrial applications?

A: The transmitter converts thermal readings from resistance temperature detectors (RTDs) into electrical signals, which are then transmitted for process monitoring and control, allowing for accurate temperature management in industrial settings.Q: What are the primary benefits of using this temperature transmitter?

A: Its high accuracy, robust efficiency of 95%, and adaptability to a broad humidity spectrum (10-90%) enable reliable and precise temperature measurement, which is crucial for maintaining optimal processes and safety in industrial environments.Q: When should this transmitter be used in an industrial setting?

A: It is ideal for use when accurate, real-time temperature monitoring and transmission are necessary for process control, particularly in environments with varying humidity and temperature demands.Q: Where can the RTD Head Mounted Temperature Transmitter be installed?

A: Thanks to its standard size and head-mounted design, it can be installed directly on industrial machinery, pipelines, or process vessels that require continuous temperature tracking.Q: What is the process for integrating this transmitter into an electrical system?

A: Integration involves mounting the transmitter in a compatible RTD head, connecting it to the system's electrical circuit, calibrating as per operational standards, and finalizing the setup for continuous process temperature monitoring.Q: How does this device improve industrial process efficiency?

A: It provides precise temperature data rapidly, allowing prompt adjustments in process controls, minimizing downtime, and enhancing overall productivity and product quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Process Control Instruments Category

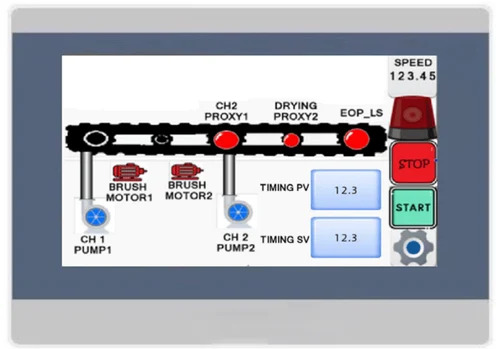

HMI Based Flex Polymer Plate Washer(Touch Screen)

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220 Volt (v)

Condition : New

Power Mode : Electric

Warranty : 1 Year

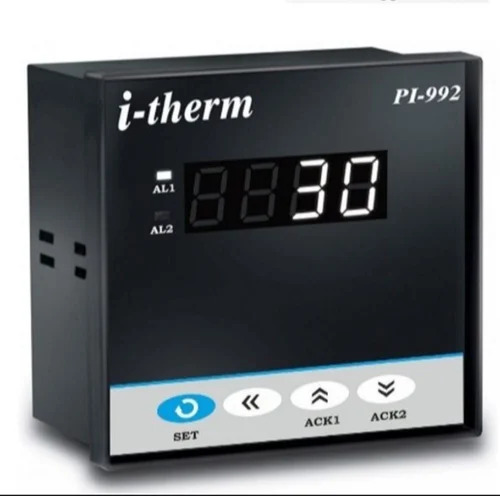

PI-992 Process Indicator

Price 1400 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 90270 Volt (v)

Condition : New

Power Mode : Electric

Warranty : 1 Year

PI-442 Digital Process Indicator

Price 1330 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 250 Volt (v)

Condition : New

Power Mode : Electric

Warranty : 1 Year

PI-88X Process Indicator

Price 2170 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 90270 Volt (v)

Condition : New

Power Mode : Electric

Warranty : 1 Year

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry